PE pipes and fittings homogeneous heat fusion joints is the most preferred jointing method in terms of performance and reliability. The principle of heat fusion is to heat two surfaces to a designated temperature, then fuse them together by application of sufficient force. This force applied causes the melted materials to flow and mix, thereby resulting in fusion.

When fused according to the pipe and/or fitting procedures, the joint area becomes as strong or stronger than the pipe itself in both tensile and pressure properties, thus homogeneously fused joints are considered leak-proof.

JOINTING ENHANCEMENT 1 - COLD-RING

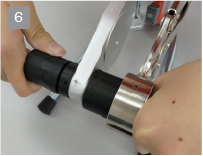

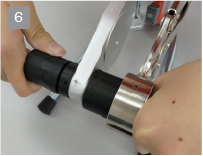

Cold-ring is a rounding clamp used to maintain the roundness of the pipe and strengthen the circumferential structure of the pipe. The positioning of Cold-ring will set and control the insertion depth of the pipe (acting as the ‘hard-stop’) during the jointing operation. The Cold-ring will not allow over-push or over-insert of the pipe into

the socket fitting, thus preventing the pipe edge crumpling or cold joint issues. The flat surrounding face of Cold-ring when push against the flat of fitting’s mouth which resulting in consistent flattened beads being formed on every joint.

The Cold-ring helps in fast and reliable installation. It can also be used repeatedly.

JOINTING ENHANCEMENT 1 - COLD-RING

Cold-ring is a rounding clamp used to maintain the roundness of the pipe and strengthen the circumferential structure of the pipe. The positioning of Cold-ring will set and control the insertion depth of the pipe (acting as the ‘hard-stop’) during the jointing operation. The Cold-ring will not allow over-push or over-insert of the pipe into

the socket fitting, thus preventing the pipe edge crumpling or cold joint issues. The flat surrounding face of Cold-ring when push against the flat of fitting’s mouth which resulting in consistent flattened beads being formed on every joint.

The Cold-ring helps in fast and reliable installation. It can also be used repeatedly.

JOINTING ENHANCEMENT 2 - ORBIT

Orbit is a proprietary design and has been developed to mark or indicate the insertion depth of a pipe conveniently, fast and to allow the immediate gross check on pipe ovality. It is an all-in-one tool caters for pipe sizes of DN 20 to DN 63 for both PE 100 PN12.5 and PN16 pipes. This full-proof design only allows respective pipe sizes to be inserted into the respective slot one at a time, hence less prone to errors and when marking and checking.

JOINTING ENHANCEMENT 2 - ORBIT

Orbit is a proprietary design and has been developed to mark or indicate the insertion depth of a pipe conveniently, fast and to allow the immediate gross check on pipe ovality. It is an all-in-one tool caters for pipe sizes of DN 20 to DN 63 for both PE 100 PN12.5 and PN16 pipes. This full-proof design only allows respective pipe sizes to be inserted into the respective slot one at a time, hence less prone to errors and when marking and checking.

JOINTING ENHANCEMENT 3 -

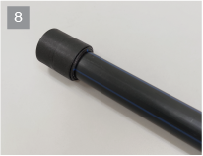

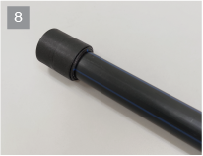

SINGLE-RING PIPE STIFFENER

Single-Ring is the newly named Pipe Stiffener or Pipe Insert that acts as the internal support for the heated pipe to prevent crumpling due to over-heating and/or over-insertion. It is essential that smaller pipe sizes with wall thickness of 3mm and below to utillize Single-Ring to prevent such phenomena.

| Nominal (mm) | PN 12.5 (SDR 13.6) | PN 16 (SDR 11) |

| 20 |  | |

| 25 |  |  |

| 32 |  |

| Nominal Size(mm) | PN 12.5 (SDR 13.6) | PN 16 (SDR 11) | ||

| 20 | Single | Double | ||

| 25 | Single | Double | Single | Double |

| 32 | Single | Double |

JOINTING ENHANCEMENT 4 - ANTI-SLIP FEMALE ELBOW

The final piping point on threaded fittings is the metal thread transition to be connected with other tapping parts. The threaded metal insert embedded inside the fitting however may “slip” or be “twisted” between the plastic body under excessive tightening force. If this occurs, water may sip through the loose gap between.

In order to avoid this, the metal insert has been designed with an extended holding position over the large elbow contact areas in opposing twist direction. This offers a “One Piece” design to achieve the Anti-Slip feature.

JOINTING ENHANCEMENT 4 - ANTI-SLIP FEMALE ELBOW

The final piping point on threaded fittings is the metal thread transition to be connected with other tapping parts. The threaded metal insert embedded inside the fitting however may “slip” or be “twisted” between the plastic body under excessive tightening force. If this occurs, water may sip through the loose gap between.

In order to avoid this, the metal insert has been designed with an extended holding position over the large elbow contact areas in opposing twist direction. This offers a “One Piece” design to achieve the Anti-Slip feature.

| CUT the pipe squarely with proper pipe cutter or by using saw with proper side-guiding in order to achieve a perpendicular cut. |  | SET UP the welding tool with the appropriate bushes. Set the welding temperature to 260 ̊C, and prepare the heating time information. |

| INSERT the pipe into the respective slot of Orbit until the end which is preset to the respective insertion depth. |  | PUSH IN both pipe & fitting by pushing them together against the flats of both surfaces within the joint time. Hold the joint until heating time achieved. |

| CLAMP ON the pipe with the Cold-ring firmly at the insertion depth position. |  | JOIN the pipe & fitting by pushing them together against the flats of both surfaces within the joint time. Hold the joint until it cools down. |

| PUT ON the Pipe-stiffener 8 into the pipe edge for pipe wall thickness below 3mm. Black color for PN16 and blue color for PN12.5 pipe. |  | CONFIRM the jointing quality whereby the outer indicator ring appear outside the pipe. |

| CUT the pipe squarely with proper pipe cutter or by using saw with proper side-guiding in order to achieve a perpendicular cut. |  | SET UP the welding tool with the appropriate bushes. Set the welding temperature to 260 ̊C, and prepare the heating time information. |

| INSERT the pipe into the respective slot of Orbit until the end which is preset to the respective insertion depth. |  | PUSH IN both pipe & fitting by pushing them together against the flats of both surfaces within the joint time. Hold the joint until heating time achieved. |

| CLAMP ON the pipe with the Cold-ring firmly at the insertion depth position. |  | JOIN the pipe & fitting by pushing them together against the flats of both surfaces within the joint time. Hold the joint until it cools down. |

| PUT ON the Pipe-stiffener 8 into the pipe edge for pipe wall thickness below 3mm. Black color for PN16 and blue color for PN12.5 pipe. |  | CONFIRM the jointing quality whereby the outer indicator ring appear outside the pipe. |

| OD, mm | Insertion Depth, mm | Heat Time, s | Joint Time, s | Cold Time, m |

| 20 | 13 | 6 | 4 | 2 |

| 25 | 15 | 7 | 4 | 3 |

| 32 | 17 | 8 | 6 | 4 |

| 40 | 19 | 12 | 6 | 4 |

| 50 | 21 | 18 | 6 | 5 |

| 63 | 25 | 25 | 8 | 6 |

| 75 | 27 | 30 | 8 | 8 |

| 90 | 30 | 40 | 10 | 8 |

| 110 | 34 | 50 | 10 | 8 |

Heating Temperature 260oC

These processing parameters are to be adhered with in order to carry out the proper installation and to produce a quality joint. The jointing process can be perfected through the usage of auxiliary enhancement tools provided, such as the Cool-ring, Orbit, Single-ring and Double-ring.

| OD, mm | Insertion Depth, mm | Heat Time, s | Joint Time, s | Cold Time, m |

| 20 | 13 | 6 | 4 | 2 |

| 25 | 15 | 7 | 4 | 3 |

| 32 | 17 | 8 | 6 | 4 |

| 40 | 19 | 12 | 6 | 4 |

| 50 | 21 | 18 | 6 | 5 |

| 63 | 25 | 25 | 8 | 6 |

| 75 | 27 | 30 | 8 | 8 |

| 90 | 30 | 40 | 10 | 8 |

| 110 | 34 | 50 | 10 | 8 |

Heating Temperature 260oC

These processing parameters are to be adhered with in order to carry out the proper installation and to produce a quality joint. The jointing process can be perfected through the usage of auxiliary enhancement tools provided, such as the Cool-ring, Orbit, Single-ring and Double-ring.